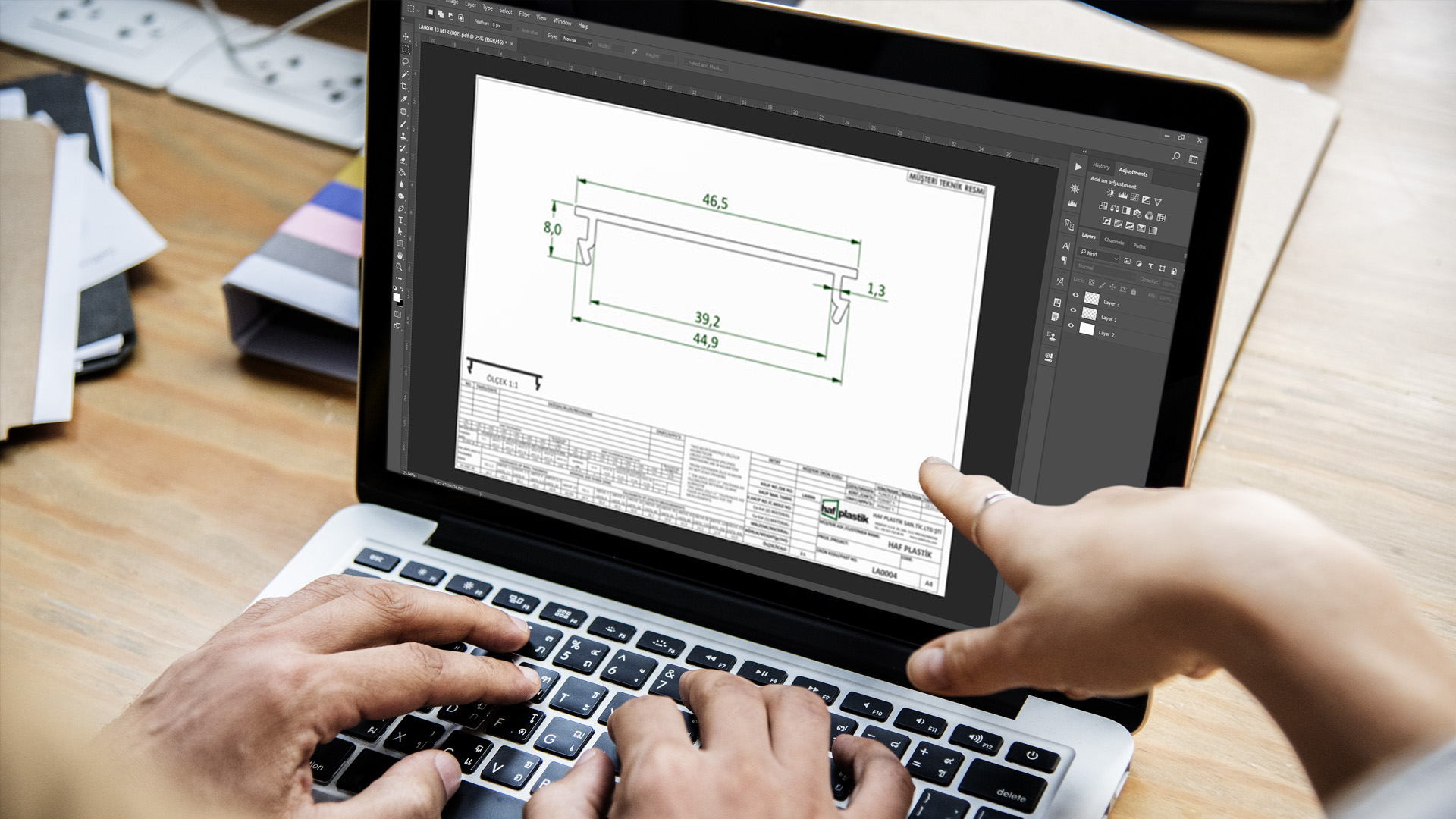

Concept development is the initial step to the optimum design solution. At HAF Plastics, we aim to identify the needs of the customers and work together on developing innovative products tailored to the specific customer needs.

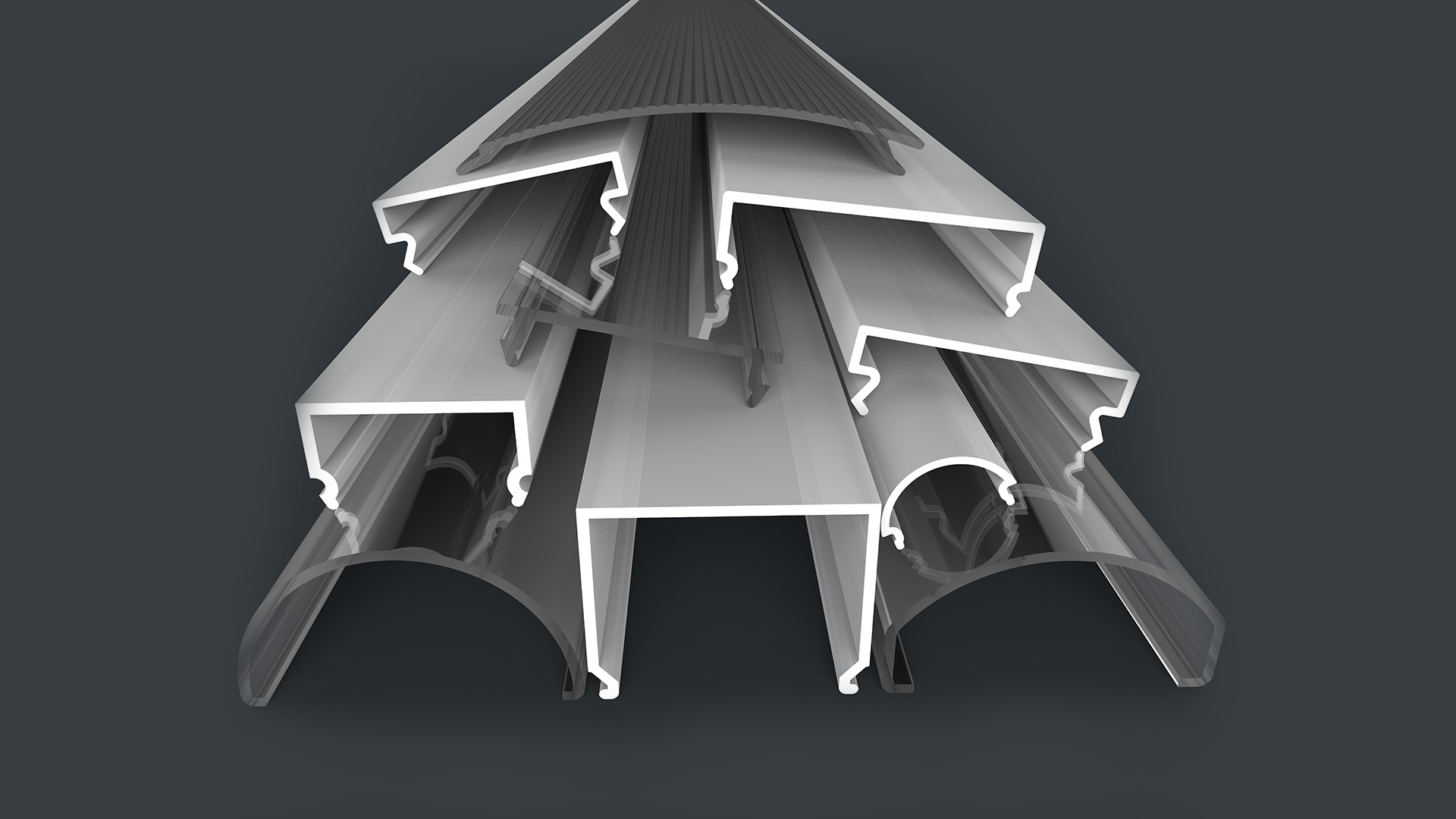

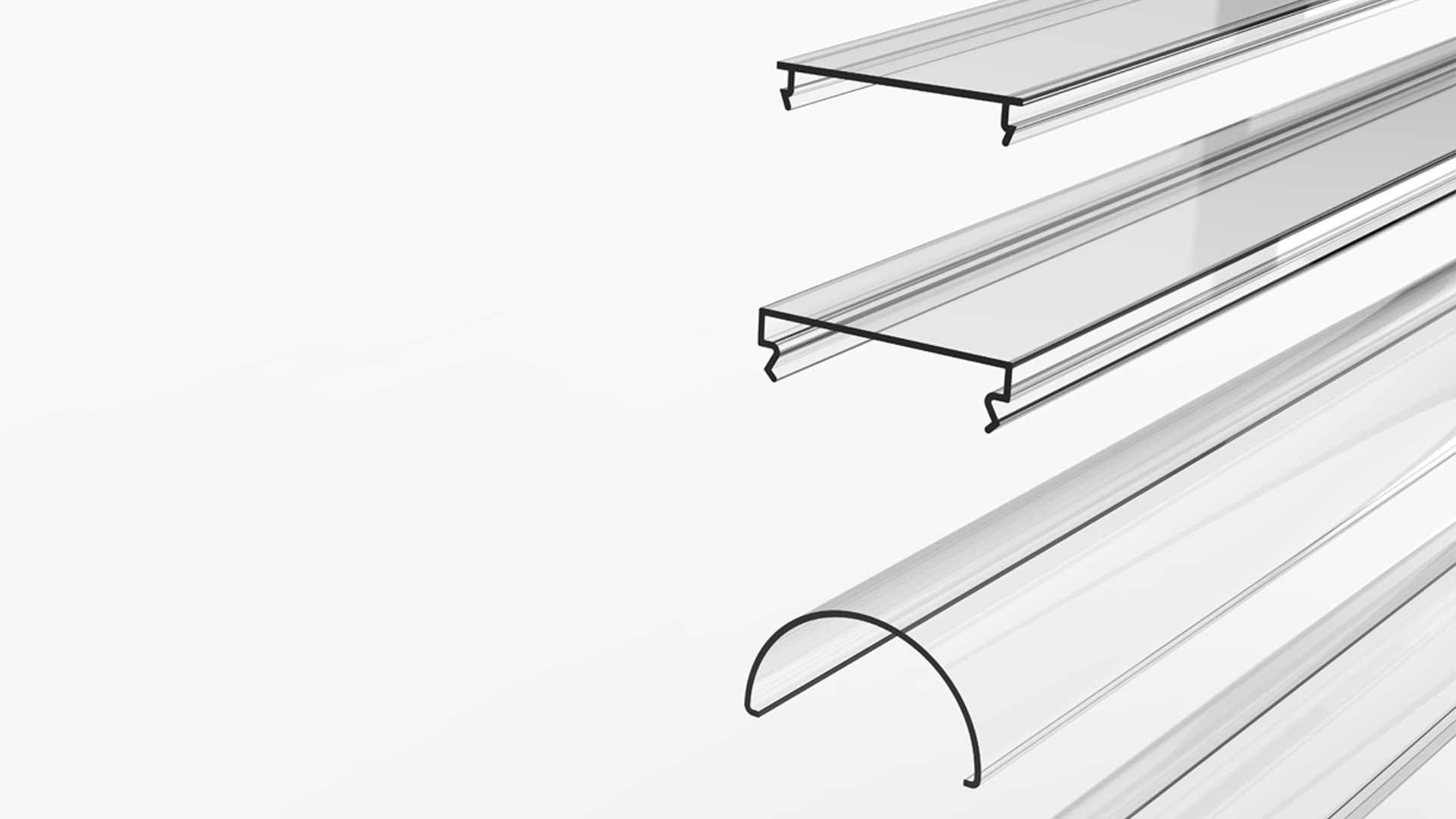

We offer speed and quality in all development phases of your extruded plastic profiles and injected parts. We transform your concept into a finished product.

Custom Solutions